Dynemix India Engineering Pvt. Ltd. is a leading Manufacturer and Exporter of Material Handling Equipment in Oman.

Our manufacturing unit is based in Ahmedabad, Gujarat, India.

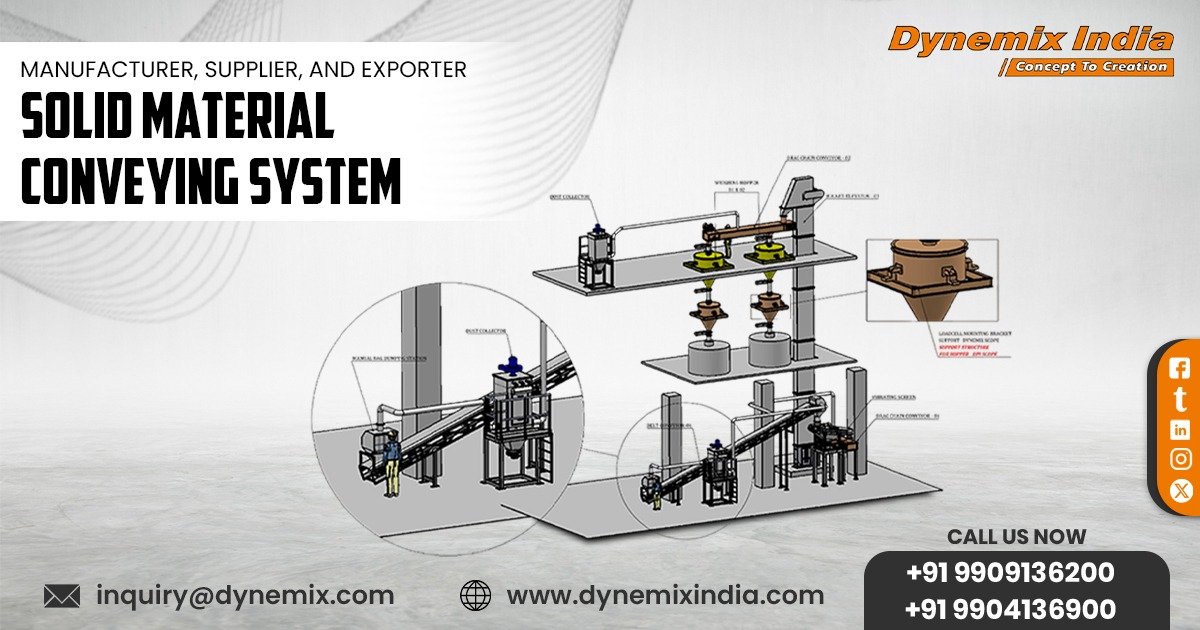

1. Introduction

- Material handling systems are essential for smooth industrial operations, ensuring that materials are moved efficiently and safely.

- They reduce manual labor, improve workflow, and enhance productivity.

- Dynemix India Engineering Pvt. Ltd. specializes in designing advanced material handling solutions tailored to industrial needs, helping companies optimize operations and minimize costs.

2. What is a Material Handling System?

- A material handling system refers to the tools, equipment, and processes used to transport, store, control, and protect materials throughout production, warehousing, distribution, and consumption.

- Types of material handling systems:

- Manual systems: Hand trucks, carts, and trolleys for small-scale operations.

- Semi-automated systems: Conveyors or hoists integrated with some automated features.

- Fully automated systems: AGVs (Automated Guided Vehicles), robotics, and fully integrated warehouse solutions.

- Key components include: conveyors, lifts, storage systems, cranes, robotics, and automated transport units.

3. Importance of Material Handling Systems in Industries

- Operational Efficiency: Streamlines movement of materials and reduces time lost in manual handling.

- Cost Reduction: Lowers labor costs by automating repetitive tasks.

- Safety Enhancement: Reduces workplace injuries associated with manual material movement.

- Space Optimization: Efficient storage solutions maximize warehouse and factory space.

- Supply Chain Support: Smoothens the flow of materials, ensuring timely production and delivery.

4. Types of Material Handling Equipment

- Conveyors:

- Belt conveyors

- Roller conveyors

- Chain conveyors

- Cranes & Hoists:

- Overhead cranes

- Jib cranes

- Electric hoists

- Automated Guided Vehicles (AGVs): Efficient for transporting materials in large factories.

- Storage & Retrieval Systems:

- Pallet racking

- Automated storage and retrieval systems (AS/RS)

- Other Equipment:

- Forklifts, trolleys, carts, and elevators for specialized material handling.

5. Factors to Consider When Choosing a Material Handling System

- Nature of Materials: Weight, size, fragility, and type of product.

- Volume and Frequency: Daily movement requirements and operational scale.

- Space Availability: Factory or warehouse layout for efficient equipment placement.

- Budget and ROI: Cost-effectiveness and long-term benefits of the system.

- Integration: Compatibility with existing machinery, software, and workflows.

6. Benefits of Implementing Material Handling Systems

- Increased Productivity: Faster material movement and reduced delays.

- Reduced Downtime: Streamlined operations minimize bottlenecks.

- Enhanced Safety: Less manual lifting reduces the risk of injuries.

- Minimized Product Damage: Gentle handling reduces breakage and spoilage.

- Scalability: Systems can grow with business needs and technological advancements.

7. Why Choose Dynemix India Engineering Pvt. Ltd.

- Customized Solutions: Designs tailored to specific industrial requirements.

- Advanced Technology: Use of automation, robotics, and intelligent systems.

- Proven Track Record: Successful projects across diverse industries.

- Quality and Safety Compliance: Adherence to industrial standards.

- Support Services: Maintenance, after-sales support, and continuous optimization.

8. FAQs:

Why are material handling systems important for industries?

They improve operational efficiency, reduce labor costs, enhance safety, minimize product damage, and optimize storage space, ensuring smooth industrial workflows.

What types of material handling equipment are available?

Common types include conveyors, cranes and hoists, forklifts, automated guided vehicles (AGVs), pallet racks, and automated storage and retrieval systems (AS/RS).

How does Dynemix India Engineering Pvt. Ltd. help industries with material handling?

Dynemix provides customized, technologically advanced solutions that integrate automation, robotics, and smart systems to improve efficiency, safety, and productivity.

What factors should I consider before choosing a material handling system?

Consider the nature of materials, volume and frequency of movement, available space, budget, ROI, and integration with existing processes or machinery.

Are material handling systems scalable for future business growth?

Yes, modern systems are designed to be scalable and adaptable, allowing businesses to expand operations or integrate new technologies without major disruptions.

Dynemix India Engineering Pvt. Ltd. is Exporter of Material Handling Equipment in Oman

and including locations in Masqaţ, Muscat, Bawshar, Şalālah, As Sīb, Maţraḩ, As Suwayq, Aş Şuwayḩirah as Sāḩil, Ar Rustāq, Al Muḑaybī, ‘Ibrī, Bahlā’, Nizwá, Samā’il, Al ‘Āmirāt, Al Buraymī, Qurayyāt, Al Madrah Samā’il, Shināş, Izkī, Ibrā’, Nakhal, Ḑank, Khaşab, Al Mazyūnah, Şuḩār, Şūr, Haymā’ and many more.

For more information or to request a quote, please contact us.

Website: www.dynemixindia.com

Phone No: +91 9909136200 | +91 9904136900

View Product: Click here