Dynemix India Engineering Pvt. Ltd. is a reliable Manufacturer of Bagging System in Ahmedabad.

Our Manufacturer unit is based in Ahmedabad, Gujarat, India.

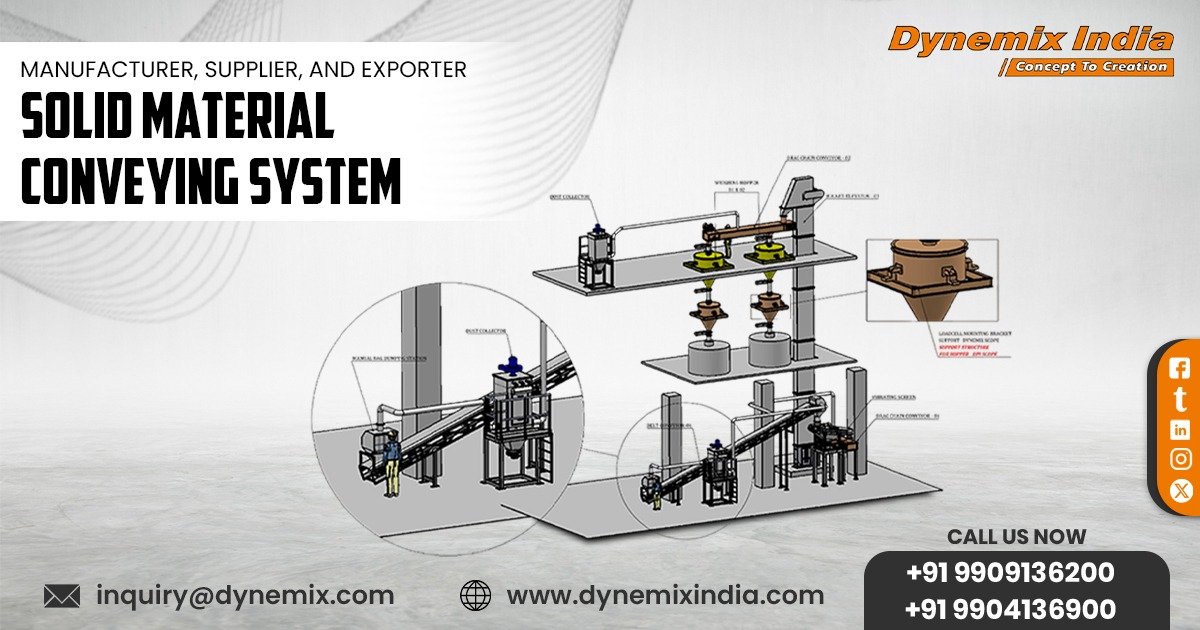

Dynemix offers bagging machinery that optimizes material handling, reduces manual effort, and ensures precise packaging for powders, granules, and bulk materials.

Work of a Bagging System

A Bagging System is an automated solution designed to weigh, fill, seal, and dispatch bags in a consistent and efficient manner.

Its key functions include:

- Accurate weighing of materials using load-cell–based measurement.

- Controlled filling of materials into various bag types.

- Automated sealing and stitching for safe and durable packaging.

- Conveying and stacking of filled bags for streamlined logistics.

- Reduction of manual labor and improvement of plant productivity.

Features of Dynemix Bagging Systems

- High-precision weighing technology for accurate material measurement.

- Automated filling mechanism suitable for powders, granules, and aggregates.

- Heavy-duty construction for long-term industrial use.

- Variable filling speeds to match different production demands.

- Dust-proof design to ensure a cleaner and safer work environment.

- User-friendly control panel with PLC-based automation.

- Flexible bag handling for HDPE, PP, paper, and laminated bags.

- Low maintenance requirements with robust components and easy servicing.

Benefits

- Improves operational efficiency by automating repetitive tasks.

- Ensures consistent bag weight, reducing product loss and quality issues.

- Enhances worker safety by minimizing manual handling.

- Increases production output with faster bagging cycles.

- Reduces wastage through precise material dispensing.

- Supports smooth logistics with uniform, well-sealed bags.

- Cost-effective solution offering long-term value and durability.

Applications

Dynemix Bagging Systems are widely used across industries such as:

- Construction materials (cement, concrete additives, mortar mix)

- Minerals and mining

- Chemicals and fertilizers

- Food processing (flour, grains, sugar, seeds)

- Pharmaceuticals and fine powders

- Agro-products and animal feed

- Plastic granules and resins

- Bulk industrial materials

FAQs

1. What types of materials can the Dynemix Bagging System handle?

It is designed to handle powders, granules, flakes, and bulk solids across various industries.

2. Can the machine be customized for specific production needs?

Yes, Dynemix offers complete customization based on capacity, bag size, material type, and automation level.

3. What bag sizes are supported?

The system supports multiple bag capacities, typically ranging from 10 kg to 50 kg, depending on requirements.

4. Does the system minimize dust during filling?

Dust-control features and sealed filling mechanisms ensure clean and safe operations.

5. What automation options are available?

Options include PLC control, auto bag placement, stitching, sealing, conveying, and stacking modules.

6. How accurate is the weighing system?

The load-cell-based weighing mechanism ensures high accuracy with minimal deviation.

7. Is maintenance difficult?

No. Dynemix designs its systems for easy access, low maintenance, and long service life.

8. How long does installation take?

Installation time varies with model complexity but is typically quick and efficiently managed by Dynemix’s technical team.

Dynemix India Engineering Pvt. Ltd. is a reliable Manufacturer of Bagging System in Ahmedabad

and also provider of Bagging System in Monaco including locations in Monaco City, La Condamine, Roquebrune-Cap-Martin, Beausoleil, Èze, Menton, Cap-d’Ail, La Turbie, Beaulieu-sur-Mer and

many more.

For more information or to request a quote, please contact us.

Website: www.dynemixindia.com

Phone No: +91 9909136200 | +91 9904136900

Email Id: inquiry@dynemix.com

View Product: Click here