Dynemix India Engineering Pvt. Ltd. is a prominent Manufacturer, Supplier, and Exporter of Slurry Preparation Plant Batch Type in Moldova.

Our Manufacturing unit is located in Ahmedabad, Gujarat, India.

Dynemix has built a reputation for delivering world-class industrial solutions that meet international standards.

Our diverse portfolio includes Pugmill Mixers, Slurry Preparation Plants, Sand Washing Systems, and various types of conveyors and feeders.

We specialize in providing tailor-made solutions across multiple industries, including construction, ceramic, mining, and infrastructure.

Our engineering excellence and client-centric approach have helped us expand our reach globally, including into European markets like Moldova.

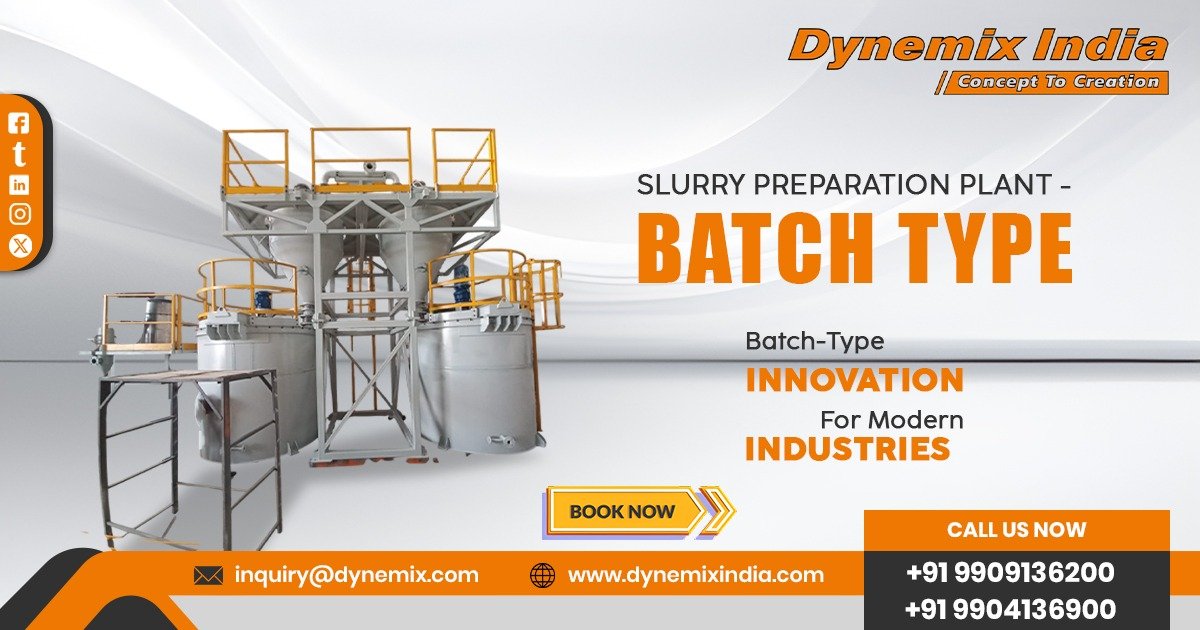

What is a Slurry Preparation Plant (Batch Type)?

A batch-type slurry plant creates uniform slurry by blending water with solid materials like clay, silica, and additives.

This type of plant works in batches rather than continuous flow, ensuring consistent quality and precision in every cycle.

Dynemix’s batch slurry plant meets ceramic, glass, and construction standards with reliable, energy-efficient, user-friendly performance.

Working of Slurry Preparation Plant Batch Type:

Raw Material Feeding: The system accurately weighs and feeds raw materials into the mixing tank.

Mixing & Agitation: High-efficiency agitators or blungers mix solid materials with water to create a uniform slurry.

Batch Processing: Automated controls ensure precise preparation of each batch by managing time, consistency, and viscosity.

Slurry Discharge & Transfer: The system discharges the prepared slurry into holding tanks or pipelines for further use in the manufacturing process.

Cleaning & Maintenance: The system is designed for easy cleaning and minimal maintenance between batches.

Features of Slurry Preparation Plant Batch Type:

Robust Construction: Made with corrosion-resistant and wear-resistant materials for long life.

Automated Controls: PLC-based system for precision and ease of operation.

Efficient Mixing: High-speed agitators ensure thorough and uniform mixing of materials.

Energy Efficient: Designed for low power consumption while maintaining high output.

Batch Accuracy: Consistent output with minimal human intervention.

Modular Design: Easy to install, expand, and maintain.

Safety Features: Built-in safety mechanisms to prevent overload and overheating.

Why Choose Dynemix Slurry Preparation Plant Batch Type in Moldova?

Trusted Indian Manufacturer: Proven track record of delivering high-performance equipment worldwide.

Tailor-Made Solutions: Customizable plant design to suit your operational needs.

Global Standards: Conforming to European safety and quality regulations.

After-Sales Support: Comprehensive technical support, training, and spare parts availability.

Competitive Pricing: World-class technology at cost-effective pricing.

Applications:

Ceramic Tile Manufacturing

Sanitary Ware Production

Glass Industry

Construction Materials

Refractories

Chemical Industries

Mining and Mineral Processing

FAQs:

Q1: What is the capacity range of your batch type slurry preparation plant?

A: We offer customizable capacities ranging from small-scale setups (500 L) to large industrial plants (10,000 L or more).

Q2: Can this plant be used for abrasive materials?

A: Yes, we use wear-resistant linings and materials to handle abrasive raw materials efficiently.

Q3: Do you provide installation and training in Moldova?

A: Absolutely. We offer full installation, commissioning, and operator training services globally, including in Moldova.

Q4: Is your plant compatible with automated production lines?

A: Yes, our slurry plants are fully integrable with automated systems and SCADA interfaces.

Q5: What maintenance is required for this plant?

A: Minimal maintenance is required. Regular checks of mixers and pumps ensure long-term reliability.

Dynemix India Engineering Pvt. Ltd. is an Exporter of Slurry Preparation Plant Batch Type in Moldova including location in Chișinău, Tiraspol, Bălți, Soroca, Bender, Cahul, Orhei, Comrat, Străşeni, Drochia, Hînceşti, Ceadîr-Lunga, Basarabeasca, Edineţ, Camenca, Ungheni, Rezina, Dubăsari, Cantemir, Șoldănești, Mărculești, Otaci, Ialoveni, Durleşti, Taraclia, Lipcani, Briceni, Maiac, Teleneşti, Ştefan Vodă, Floreşti, Rîşcani, Cricova, Cimişlia, Glodeni, Grigoriopol, Leova, Cupcini, Ocniţa, Iargara, Vulcănești, Crasnoe, Corneşti, Vatra, Codru, Novotiraspolsky, Fălești, Nisporeni, Călăraşi, Căușeni, Anenii Noi.

If you would like more information or to request a quote, feel free to contact us.

View Product: Click here