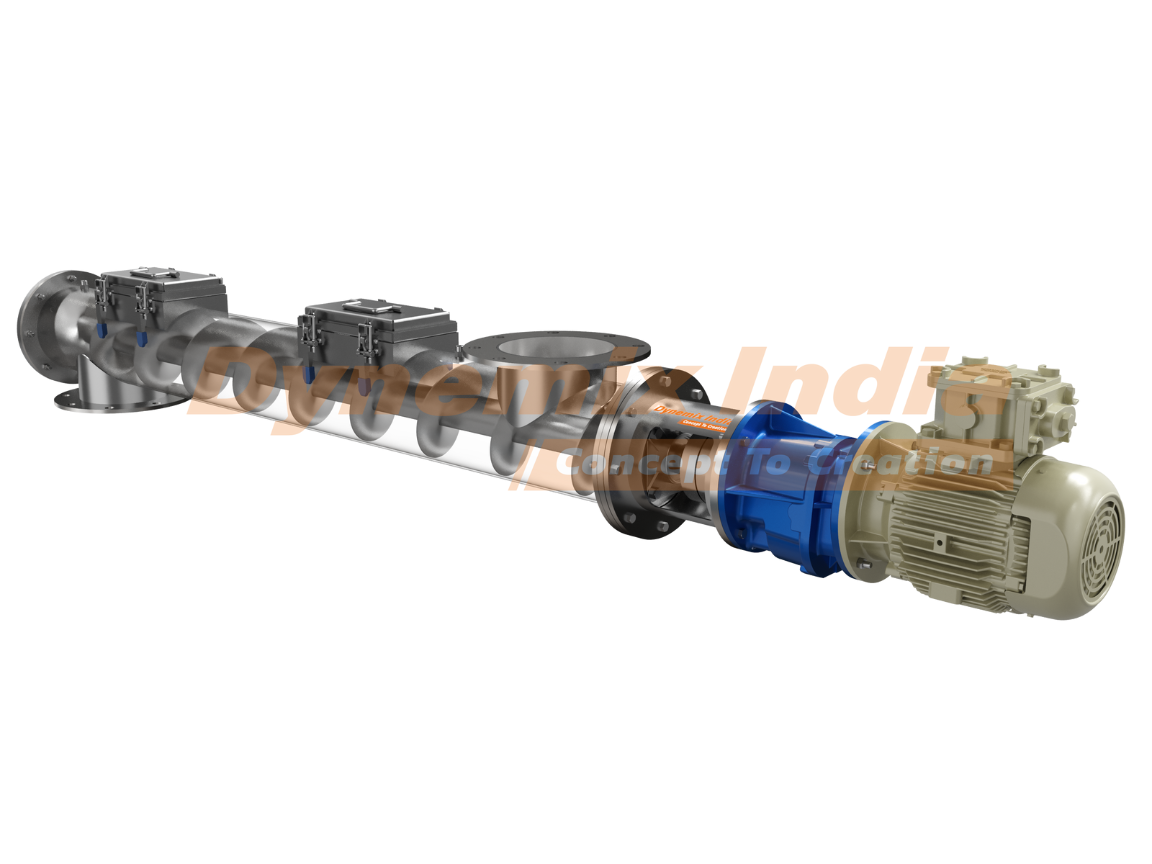

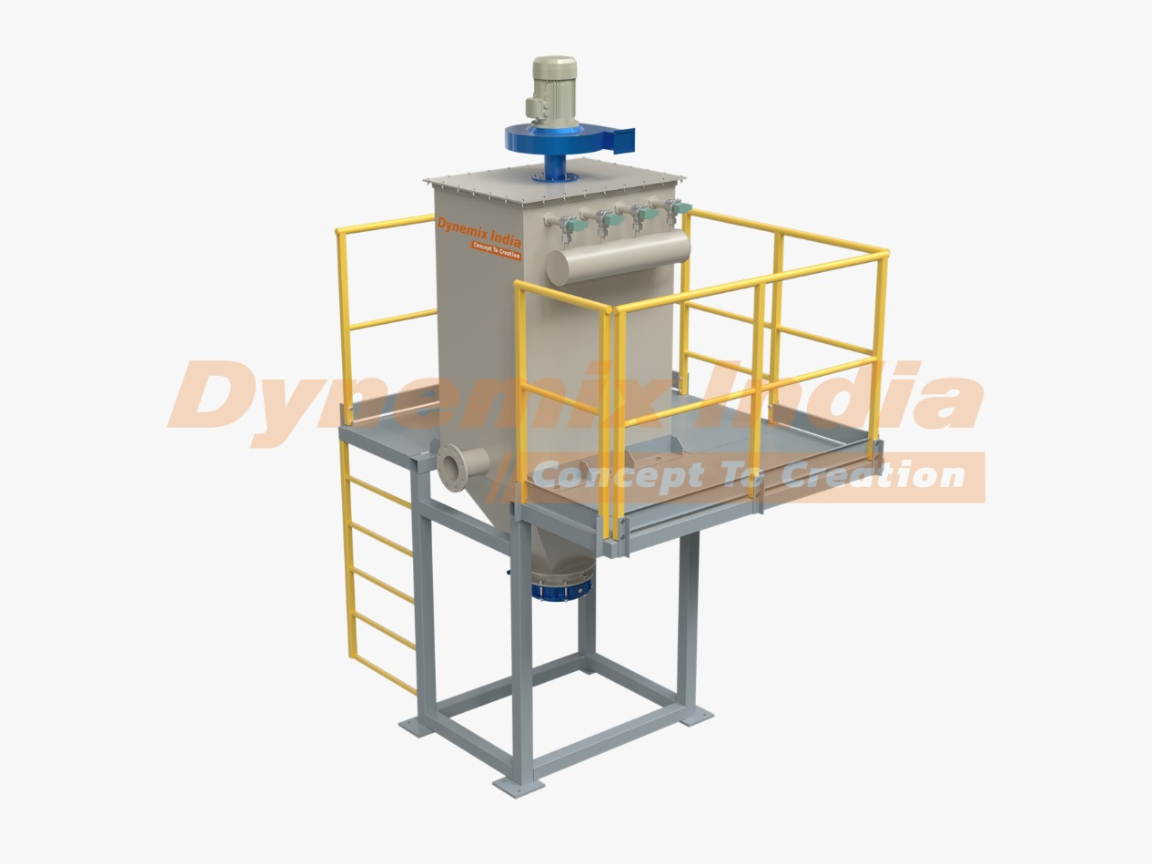

For industries that require substantial quantities of lime slurry, an effective and cost-efficient solution is the on-site slaking of quick lime. This process involves injecting quick lime into an agitated slaking tank while maintaining a high concentration. The reaction between quick lime and water is exothermic, producing heat and steam. To handle the excess steam, a dust scrubber installed on top of the tank ensures proper aeration and minimizes dust emissions. The slaking process is automated for precision and safety, utilizing a temperature probe, electronic flowmeter, and ultrasonic level probe to monitor conditions closely. Once the quick lime is fully slaked, the resulting lime slurry overflows into a dilution tank, where water is added to achieve the desired final concentration for effective pumping.

In contrast, some processes may require a simpler approach that doesn’t necessitate high-quality lime slurry. Batch slakers, or mix tanks, are designed to produce a precisely metered slurry, making them ideal for applications with relatively low slurry production rates. They accommodate minimal variations in the quality of quicklime and water sources. Batch slakers are particularly beneficial for operations with a consistent supply of both quicklime and water, allowing for a steady, small volume of hydrated lime slurry to be produced daily.

| product | Lime Slaker |

| Power Consumption | 10kW |

| Body Material | SS |

| Frequency | 60 Hz |

| Voltage | 380V |

| Brand | Dynemix India Engg Private Limited |

WhatsApp us