Dynemix India Engineering Pvt. Ltd. is a reliable Manufacturer of Solid Material Conveying System in Ahmedabad.

Our Manufacturer unit is based in Ahmedabad, Gujarat, India.

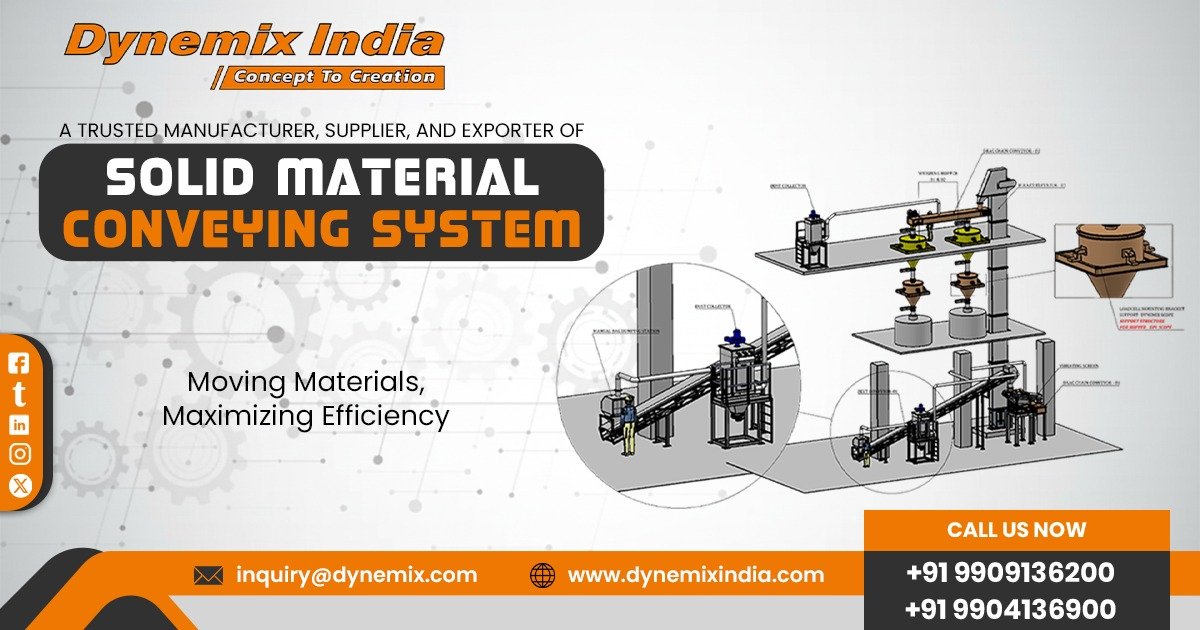

A Solid Material Conveying System plays a vital role in modern industrial operations, ensuring reliable, efficient, and contamination-free transfer of bulk solids from one process to another.

Dynemix India Engineering Pvt. Ltd. specialize in designing and manufacturing advanced conveying solutions customized to meet the unique needs of diverse industries.

Our systems are engineered with precision, built for durability, and optimized to enhance productivity while reducing operational downtime.

Work of Solid Material Conveying System

A Solid Material Conveying System is designed to transport dry bulk materials such as powders, granules, flakes, pellets, and other solid forms efficiently within a plant.

The system ensures seamless flow of material with minimal human intervention.

How It Works

- Material Feeding: Bulk solids are loaded through hoppers or feed points.

- Conveying Mechanism: Using technologies such as pneumatic, mechanical, or vacuum conveying, materials move through enclosed pipelines or belts.

- Material Transfer: The system shifts solids to silos, bins, mixers, packaging units, or production lines.

- Controlled Discharge: Provides accurate material flow with controlled discharge rates for consistent processing.

- Automation Integration: Equipped with sensors, controls, and monitoring systems for smooth, automated conveying.

Why Choose Our Solid Material Conveying System

Advantages of Dynemix India Engineering Pvt. Ltd.:

- Tailor-Made Solutions that perfectly match your plant layout and material characteristics.

- High Efficiency to reduce energy consumption and maximize flow capacity.

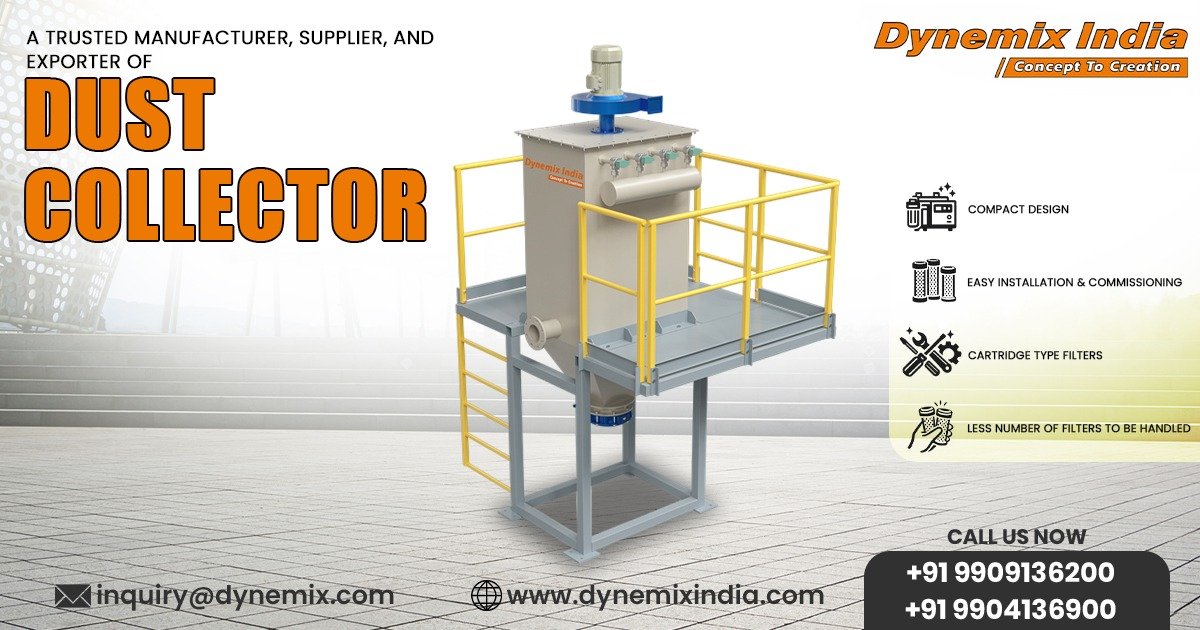

- Dust-Free Operation ensuring a clean, safe, and pollution-free environment.

- Minimal Maintenance with durable components for long service life.

- Advanced Automation for precise control, real-time monitoring, and seamless integration with existing systems.

- Expert Engineering Team with years of experience in bulk material handling.

- Reliable After-Sales Support through installation, commissioning, and maintenance.

Features

- Robust Construction: Built with high-grade materials for maximum durability.

- Flexible Design: Suitable for powders, granules, and irregular solid forms.

- High Conveying Capacity: Designed for both short-distance and long-distance material transfer.

- Low Power Consumption: Engineered for optimum operational efficiency.

- Enclosed Conveying: Prevents product contamination and reduces material loss.

- Noise-Free Operation: Smooth functioning with minimal vibration and sound.

- User-Friendly Control Panels: Easy monitoring and control for operators.

- Safety Mechanisms: Equipped with overload protection, emergency stop, and monitoring sensors.

Application

Our Solid Material Conveying Systems are extensively used across various industrial sectors, including:

- Cement & Construction Industry

- Chemical & Petrochemical Plants

- Food & Beverage Industry

- Pharmaceutical Manufacturing

- Plastic & Polymer Industry

- Mining & Minerals

- Agriculture & Fertilizers

- Paints & Coatings

- Foundry & Metallurgical Units

- Textile & Paper Industry

FAQs

1. What materials can your Solid Material Conveying System handle?

Our systems can handle a wide range of materials including powders, granules, flakes, pellets, cement, fly ash, chemicals, food ingredients, and more.

2. Are your conveying systems customizable?

Yes. We offer fully customized solutions based on your material type, plant layout, conveying distance, and production capacity.

3. What is the maintenance requirement?

Our systems are designed for low maintenance. Regular inspection and cleaning ensure long-term performance.

4. Do you provide installation and commissioning support?

Our expert engineers assist with installation, commissioning, training, and after-sales service.

5. What conveying technologies do you offer?

We provide pneumatic conveying, mechanical conveying, vacuum conveying, and pressure conveying systems as per client requirements.

6. Is the operation fully automated?

Yes, our systems can be integrated with PLC/SCADA automation for real-time monitoring and control.

Dynemix India Engineering Pvt. Ltd. is a reliable Manufacturer of Solid Material Conveying System in Ahmedabad and also provider of Solid Material Conveying System in Albania including locations in Tirana, Durrës, Vlorë, Kamëz, Fier, Shkodër, Elbasan, Korçë, Sarandë, Berat, Lushnjë, Kavajë, Gjirokastër, Pogradec, Fushë-Krujë, Laç, Kukës, Sukth, Buçimas, Lezhë, Patos, Peshkopi, Librazhd-Qendër, Kuçovë, Krujë, Burrel, Perondi, Libonik, Rrëshen, Belsh, Divjakë, Gramsh, Mamurras, Bulqizë, Vau i Dejës, Shëngjin, Ballsh, Shijak, Bilisht, Rrogozhinë, Librazhd, Cërrik, Roskovec, Manzë, Peqin, Krumë, Përmet, Përrenjas-Fshat, Prrenjas, Delvinë, Orikum, Bajram Curri, Vorë, Këlcyrë, Ura Vajgurore, Himarë, Rubik, Tepelenë, Poliçan, Çorovodë, Ersekë, Maliq, Koplik, Pukë, Lazarat, Memaliaj, Velçan, Banaj, Fushë-Arrëz, Krrabë, Selenicë, Voskopojë, Bitinckë, Drenovë, Libohovë, Reps, Gjinkar, Krastë, and many more.

For more information or to request a quote, please contact us.

Website: www.dynemixindia.com

Phone No: +91 9909136200 | +91 9904136900

Email Id: inquiry@dynemix.com

View Product: Click here