Dynemix India Engineering Pvt. Ltd. is a reliable Exporter of Lump Breaker in Oman.

Our Manufacturing unit is based in Ahmedabad, Gujarat, India.

Dynemix India Engineering Pvt. Ltd. is a leading engineering and manufacturing company specializing in material handling equipment.

With a reputation for precision, innovation, and durability, Dynemix has become a trusted name across multiple industries including food processing, pharmaceuticals, chemicals, and construction.

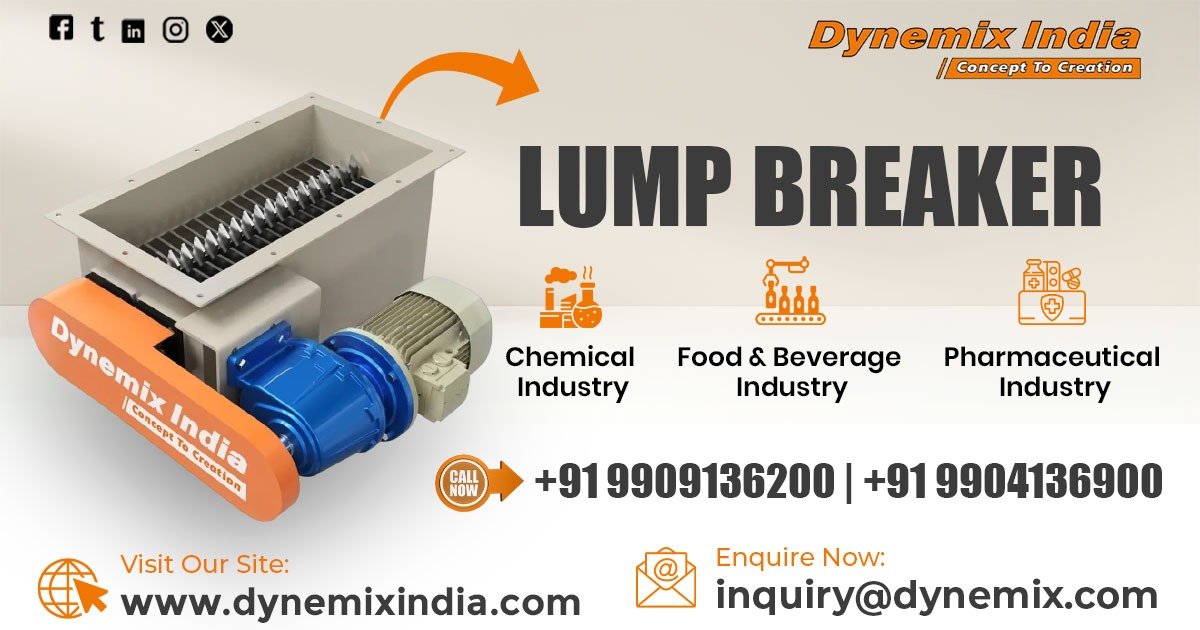

A Lump Breaker, also known as a lump crusher, is an essential machine used in material handling industries.

It breaks down large clumps of bulk solids and powders into smaller, more manageable sizes to ensure smooth downstream processing.

Work of Lump Breaker

The primary function of a Lump Breaker is to:

- Crush and reduce oversized materials into smaller particles.

- Prevent clogging and jamming in conveying systems.

- Ensure consistent product flow and improve the efficiency of downstream processes such as mixing or packaging.

Features of Dynemix Lump Breakers

- Robust Construction – Made with high-quality stainless steel for durability and hygiene.

- Custom Design – Available in various sizes and configurations to suit diverse materials.

- Low Maintenance – Engineered for easy cleaning and minimal downtime.

- High Efficiency – Capable of processing both wet and dry lumps.

- Compact Design – Space-saving layout suitable for confined processing environments.

Technical Specification:

| Material | Mild Steel |

| Voltage | 240V |

| Frequency | 50 Hz |

| Surface Treatment | Painted |

| Capacity | 25 TPH |

| Power | 15 kW |

Working Principle of Lump Breaker

The Dynemix Lump Breaker operates using rotating blades or arms that pass through a fixed or rotating screen.

When materials enter the breaker, the blades crush or shear them against the screen, effectively breaking them down. The reduced particles then fall through the screen for further processing.

Common Applications & Uses

Dynemix Lump Breakers are widely used in:

- Chemical industries – For breaking down agglomerated powders.

- Food processing units – To maintain flowability of ingredients like sugar, salt, or spices.

- Pharmaceuticals – For uniform particle size before mixing or tablet formation.

- Cement & Construction – For crushing hardened materials and returning them to the production cycle.

- Plastics & Polymers – For reclaiming or reprocessing leftover materials.

Frequently Asked Questions (FAQs)

1. Why choose Dynemix Lump Breakers?

Dynemix provides industry-proven solutions that are robust, easy to maintain, and tailored for your exact material processing needs.

2. Can the Lump Breaker be customized?

Yes, Dynemix offers complete customization based on size, material, and industry-specific requirements.

3. Is it suitable for wet materials?

Yes, the Lump Breaker is designed to handle both wet and dry materials efficiently.

4. What industries benefit most from Lump Breakers?

Pharmaceutical, food, chemical, plastic, and cement industries benefit the most due to the need for consistent material size and flow.

5. Does Dynemix export to Oman?

Yes, Dynemix India Engineering Pvt. Ltd. is a trusted exporter of Lump Breakers in Oman and supports clients with installation and after-sales services.

Dynemix India Engineering Pvt. Ltd. is an Exporter of Lump Breaker in Oman including location in Muscat, Sur, Nizwa, Salalah, Sohar, Rustaq, Mutrah, Bahla, Khasab, Seeb, Ibri, Izki, Samail, Al Suwayq, Ibra, Qurayyat, Shinas, Haima, Saham, Bidbid, Bawshar, Al Hamra, Bidiyah, Barka, Adam, Liwa, Al Buraimi Governorate, Al Buraimi, Nakhal, Saiq, Manah, Duqm, Raysut, Thumrait, Jalan Bani Buhassan, Al Ashkharah, Jabrin, Tan’am, Dhank, Al Awabi, Al Khaburah, Al-Mudhaibi, Al Qabil, Al-Musannah, Yanqul, Buraimi, Madha, Mirbat, Kumzar and many more.

For more information or to request a quote, please contact us.

View Product: Click here