Dynemix India Engineering Pvt. Ltd. offers a Lime Powder Handling System Turnkey Project designed to streamline the storage, conveying, and dosing of lime powder for industrial applications.

Our turnkey solution ensures efficient material handling, minimal product loss, and safe operations, making it ideal for industries like cement, steel, chemical, and power plants.

Dynemix India provides customized solutions that meet international standards while optimizing production efficiency.

Our Manufacturing unit is located in Ahmedabad, Gujarat, India.

Why Choose Our Lime Powder Handling System?

- Turnkey Solutions: From design, fabrication, installation, to commissioning, we provide end-to-end solutions.

- High Efficiency: Our system ensures smooth flow and minimal wastage of lime powder.

- Safety Compliance: Designed to reduce dust emissions and prevent material spillage.

- Customized Design: Tailored to meet specific plant requirements and production capacity.

- Durable Components: Made from high-quality materials ensuring long-lasting performance.

- Automation Ready: Integrated with control systems for precise dosing and monitoring.

Work Process of Lime Powder Handling System

- Feeding: Lime powder is fed into the system through hoppers or silos.

- Conveying: Pneumatic or mechanical conveyors transfer lime powder to the desired location.

- Screening & Filtration: Ensures only fine particles are moved, reducing blockages.

- Dosing & Weighing: Precise dosing units measure the required quantity of lime powder for the process.

- Storage: Stored in silos or bins with dust-proof and airtight mechanisms.

- Discharge: Lime powder is discharged into process lines or packaging units safely.

Components Used in Lime Powder Handling System

- Hoppers & Silos: For storage and controlled feeding.

- Pneumatic Conveyors / Screw Conveyors: For efficient powder transport.

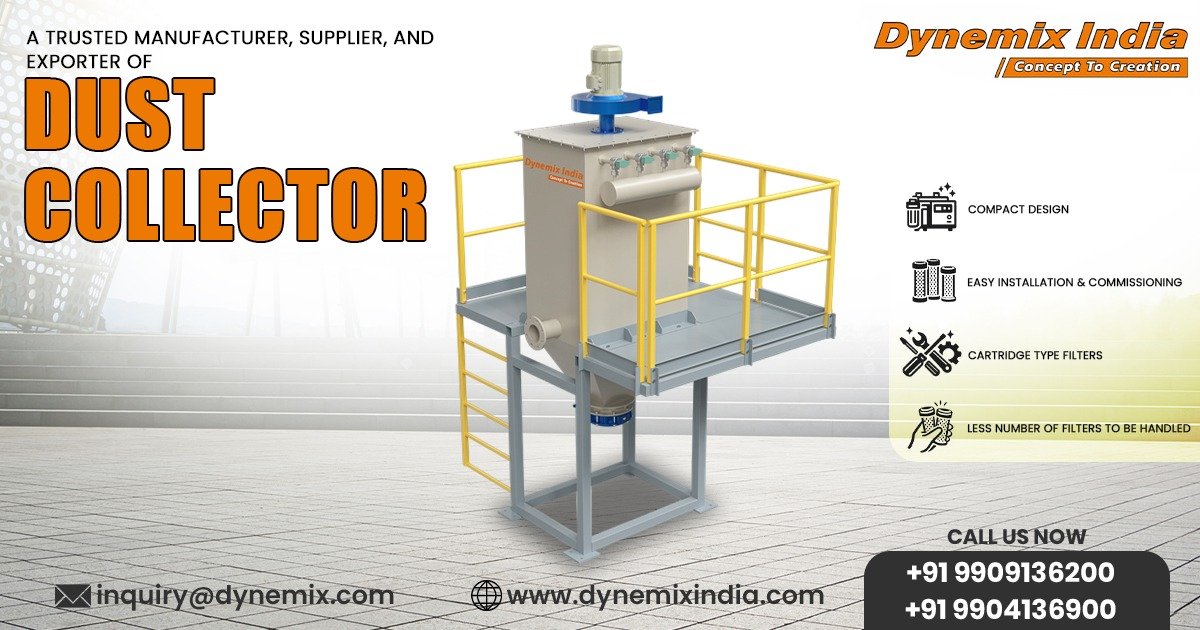

- Dust Collectors & Filters: To reduce environmental pollution.

- Dosing Units & Weighers: For accurate quantity control.

- Valves & Chutes: For smooth material flow and discharge.

- Automation & Control Panels: For monitoring and system optimization.

Uses of Lime Powder Handling System

- Cement Industry: For lime feeding in cement manufacturing.

- Steel Plants: Used in flue gas treatment and slag processing.

- Chemical Industry: For neutralization and chemical reaction processes.

- Power Plants: As part of flue gas desulfurization.

- Environmental Applications: For water treatment and pollution control.

FAQs

1. What is a lime powder handling system?

A system designed to store, convey, dose, and discharge lime powder safely and efficiently in industrial processes.

2. Is your system suitable for large-scale production?

Yes, our turnkey solutions are scalable for small, medium, and large-scale industries.

3. How do you prevent dust emissions?

We use dust collectors, filters, and airtight hoppers to ensure a clean and safe working environment.

4. Can the system be automated?

Absolutely. Our systems are designed with automation and control panels for precise operation.

5. What industries can benefit from this system?

Cement, steel, chemical, power plants, and environmental sectors primarily.

Dynemix India Engineering Pvt. Ltd. is provider of Lime Powder Handling System Turnkey Project

in Spain and including locations in Madrid, Barcelona, Valencia, Sevilla, Zaragoza, Málaga, Las Palmas de Gran Canaria, Bilbao, Murcia, Valladolid, Córdoba, Palma de Mallorca, Vigo, Alicante, Gijón, Hospital et de Llobregat, Granada, La Coruña, Vitoria-Gasteiz, Badalona, Santa Cruzde (Tenerife), Oviedo, Móstoles, Elche, Sabadell, Santander, Jérez de la Frontera, San Sebastián, Leganés, Almería, Cartagena, Tarrasa, Alcaláde Henares, Fuenlabrada, Pamplona, Burgos, Salamanca, Albacete, León, Getafe, Alcorcón, Cádiz, Huelva, Castellón de la Plana, Badajoz, Logroño, Santa Coloma de Gramanet, La Laguna, Lleida, Tarragona and many more.

For more information or to request a quote, please contact us.

Website: www.dynemixindia.com

Phone No: +91 9909136200 | +91 9904136900

View Product: Click here