Dynemix India Engineering Pvt. Ltd. is a globally recognized Manufacturer, Supplier, and Exporter of Manual Bag Dumping Station in Norway.

Our Manual Bag Dumping Station is engineered to meet strict hygiene, safety, and operational standards for food, chemicals, plastics, and construction.

Built to eliminate dust emissions and material loss, our stations ensure safer working environments and improved production efficiency.

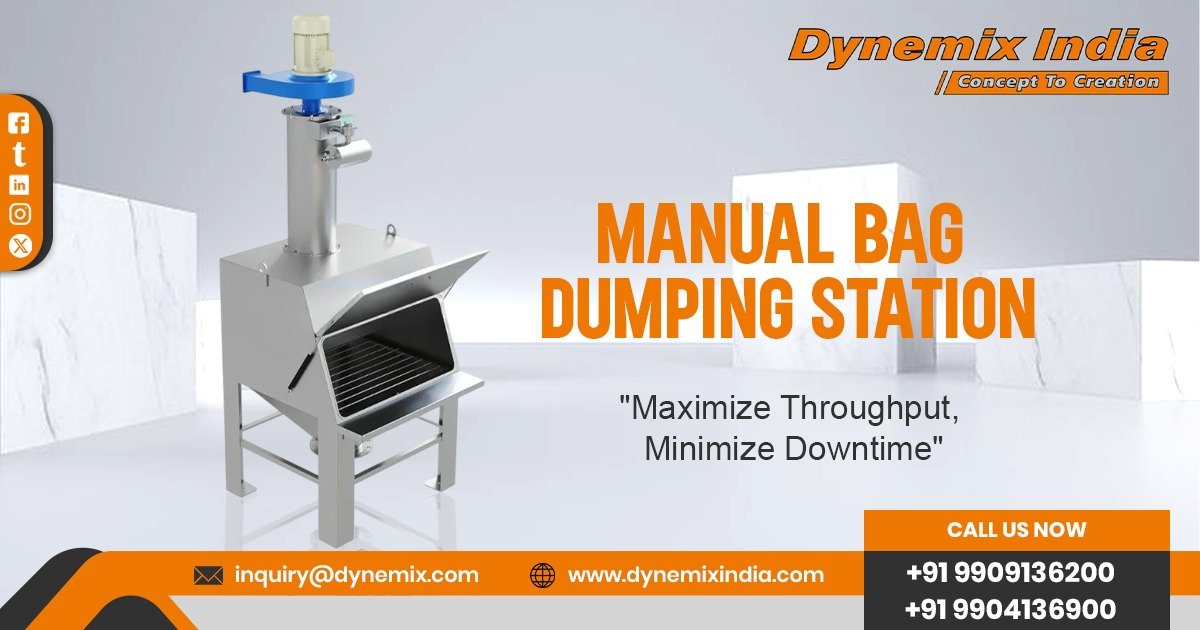

About the Product – Manual Bag Dumping Station

The Dynemix Manual Bag Dumping Station enables manual unloading of small to medium bags, minimizing dust and maximizing recovery.

This system is ideal for powder and bulk material handling operations in enclosed production environments.

Why Choose Dynemix India Engineering Pvt. Ltd. for Norway?

Trusted Exporter with International Reach

Precision-Engineered Equipment Built to Last

Excellent After-Sales Support and Spare Parts Availability

Competitive Pricing with Global Quality Standards

CE-Compliant Designs for European Markets

Features:

Ergonomic Design: Safe and comfortable working posture for operators

Inbuilt Dust Collection System: Integrated pulse jet filter and ID fan to eliminate airborne dust

Gas Spring Access Door: Easy-to-operate door for hassle-free bag emptying

Custom Product Outlet Chute: Tailored to suit your specific process line

Manual or Vacuum-Assisted Loading: Enhanced efficiency with vacuum manipulator compatibility

Robust Construction: Made from high-grade stainless steel (SS) or mild steel (MS)

Easy Maintenance: Simplified cleaning and maintenance protocols

Technical Specifications:

Product Name: Manual Bag Dumping Station

Manufacturer: Dynemix India Engineering Pvt. Ltd.

Power Source: Electrical

Voltage: 415V AC

Lifting Capacity: Up to 50 kg per bag

Usage/Application: Powder and bulk solids

Material Construction: Stainless Steel / Mild Steel

Benefits:

Improved Workplace Safety – Dust-free operation reduces respiratory risks

Enhanced Operational Efficiency – Minimizes material wastage and downtime

Environmentally Friendly – Built-in filtration ensures clean air discharge

Low Housekeeping Needs – Clean material transfer reduces post-operation cleanup

Regulatory Compliance – Helps meet safety and environmental standards in Norway and EU

Applications:

Food & Beverage Industry

Chemical Manufacturing Plants

Plastic and Resin Processing Units

Building and Construction Material Plants

Pharmaceutical and Nutraceutical Industries

Frequently Asked Questions (FAQs):

Q1. Can this system be customized for my specific process?

Yes. We offer complete customization, including outlet chute dimensions, dust collection systems, and material of construction.

Q2. Is the system compliant with Norwegian and EU safety regulations?

Absolutely. Our equipment is designed and manufactured to meet international safety and environmental compliance standards.

Q3. What kind of materials can be handled?

The station is ideal for powders, fine granules, and bulk solids used in food, chemical, and construction industries.

Q4. How does the dust extraction system work?

An inbuilt pulse jet filter and ID fan actively capture dust during the bag cutting and emptying process, ensuring a dust-free operation.

Q5. Is operator training required?

Minimal training is required. The system is user-friendly and includes operational manuals and remote support.

Dynemix India Engineering Pvt. Ltd. is an Exporter of Manual Bag Dumping Station in Norway including location in Amsterdam, Groningen, Breda, Utrecht, Rotterdam, Dordrecht, The Hague, Eindhoven, Nijmegen, Almere, Maastricht, Arnhem, Zwolle, Leiden, Deventer, Amersfoort, Middelburg, Gouda, ‘s-Hertogenbosch, Haarlem, Apeldoorn, Enschede, Zaanstad, Delft, Leeuwarden, Alkmaar, Zoetermeer, Rijswijk, Hilversum, Vlaardingen, Lelystad, Hoorn, Zutphen, Assen, Schiedam, Wageningen, Helmond, Almelo, Enkhuizen, Hengelo, Oldenzaal, Beverwijk, Heerlen, Kerkrade, Roermond, Culemborg, Doesburg, Harderwijk, Maassluis, Tiel, Nieuwegein.

For more information or to request a quote, feel free to contact us.

View Product: Click here