Dynemix India Engineering Pvt. Ltd. is a leading Exporter of Bucket Elevator in Bahrain.

Our Manufacturing unit is based in Ahmedabad, Gujarat, India.

About Dynemix India Engineering Pvt. Ltd.

Dynemix India Engineering Pvt. Ltd., based in Ahmedabad, Gujarat, is a technology-driven manufacturer and exporter of material-handling solutions.

With over 30 years of experience, they have handled turnkey projects across more than 15 countries, serving industries like construction, chemicals, pharma, textiles, plastics, power, and food processing.

Dynemix emphasizes innovation, quality, and client-centric custom solutions backed by robust infrastructure and SCADA support.

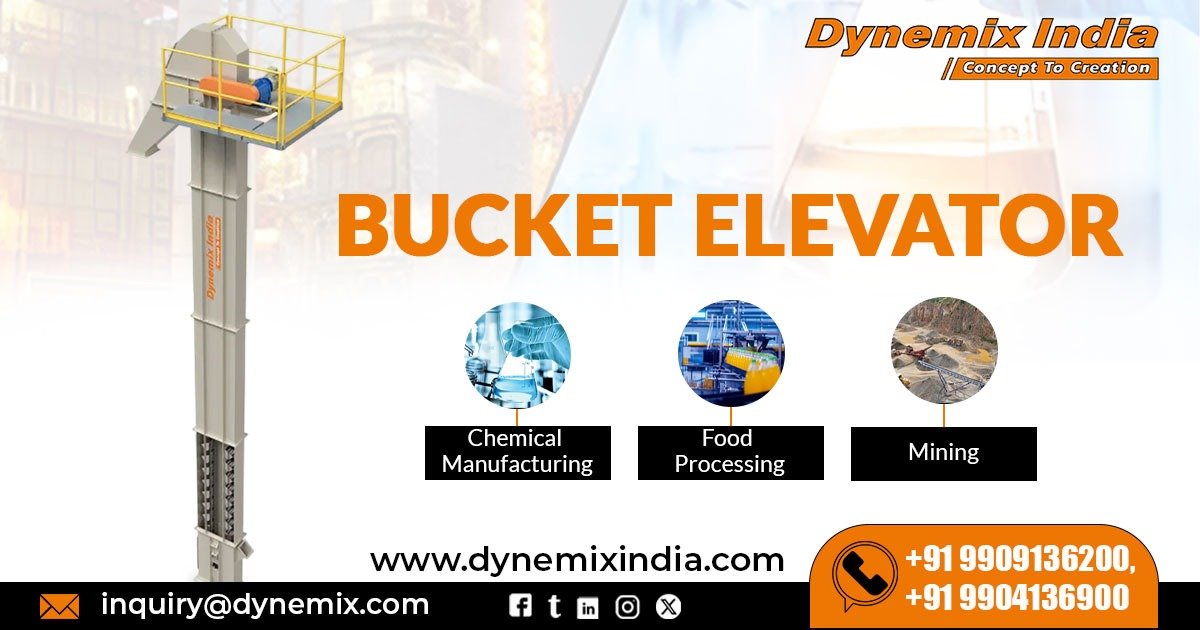

What Is a Bucket Elevator?

A bucket elevator is a vertical conveyor system used to move bulk materials—such as grains, powders, granules, and small lumps—from lower to higher elevations.

It consists of buckets attached to a belt or chain running over pulleys or sprockets, enclosed within a casing to contain dust and material flow.

What Does a Bucket Elevator Do?

- Vertical transport: It elevates materials vertically in industrial settings that require height-efficient transfer.

- Material handling: Ideal for grains, fertilizers, cement, chemicals, biomass and more.

- Applications: Widely used in agriculture, mining, cement, chemical, food processing, power, recycling, and industrial material handling industries vgprocess.com.

How It Works

- Loading (Boot section): Material is fed into the bottom of the elevator via hopper, chute, or feed gusset

- Lifting: As the system runs, buckets attached to the belt or chain ascend, carrying the load upward.

- Discharge: At the top, the system discharges materials using centrifugal force in fast-running designs or gravity/mechanical tipping in slow-speed continuous or positive discharge designs.

- Return: Empty buckets return down to the boot to repeat the cycle, enclosed to contain dust and prevent spillage.

Features of Dynemix Bucket Elevators:

While Dynemix’s detailed spec sheet isn’t publicly listed, manufacturers typically offer features such as:

- Modular, steel casing—galvanized or painted for durability and weather resistance

- Options for chain or belt drive systems depending on load and speed needs

- Various bucket materials: steel, stainless steel, HDPE, or wear liners for abrasive materials

- Accessories like inspection hatches, dust hoods, belt/chain tensioners, speed sensors, zero-speed switches, and explosion vents (ATEX) when needed.

Dynemix emphasizes precision, quality, and tailored engineering to meet client-specific process and environmental requirements.

Uses & Industries Served:

Dynemix bucket elevators (and bucket elevators in general) are utilized for:

- Agriculture & Grain Handling: Transporting grains, seeds, animal feed into silos and processing lines.

- Construction & Cement Plants: Elevating cement powders, fly ash, limestone, aggregates.

- Chemical & Fertilizer: Conveying powdered chemicals, resins, pigments, additives.

- Food Processing: Moving flour, sugar, salt, spices, starches in sanitary designs.

- Mining & Minerals: Handling ores, coal, gravel, crushed rock.

- Power & Biomass: Lifting coal, pellets, biomass fuels.

- Waste & Recycling: Elevating sorted materials like plastics, wood chips.

FAQs

Q: Can bucket elevators handle sticky or moist materials?

A: They perform poorly with sticky, cohesive or high-moisture materials (e.g. press mud, wet clay), since these can clog buckets and reduce capacity.

Q: What vertical heights and capacities are typical?

A: Standard models handle up to ~250 t/h with lift heights up to ~50 m; heavy-duty designs can exceed hundreds of tons per hour and heights beyond depending on custom engineering.

Q: How is maintenance handled?

A: Regular inspections of belt/chain tension, bucket wear, alignment, bearings, and take‑up assemblies are essential. Many systems include access hatches, take-up units, and instrumentation to monitor running speed and plug detection.

Q: Are bucket elevators safe for dust and explosive materials?

A: Yes—enclosed systems minimize dust, and features like explosion vents, dust extraction hoods, and ATEX compliance are available for hazardous applications.

Dynemix India Engineering Pvt. Ltd. is an Exporter of Bucket Elevator in Bahrain including location in

Manama, Al Muharraq, Hamad Town, Jidhafs, Isa Town, Sitra, Halat an Naim, Kaflan, Karbabad, Jabalat Habashi, Ain al Dar, Hillat Abd al Salih, Al Muqsha, Manee, Al Muwaylighah, Al Busaiteen, Rayya, Arad, Qalali, Samahij, Al Dair, Halat as Sultah, Az Zimmah, Halat al Khulayfat, Al Hidd, Umm ash Shajar, Al Hujayr, Al Nuwaidrat, Al Jubailat, Al Qarya, Hala, Marquban, Sufala, Halat Umm al Bayd, Al Akr, Al Ma’ameer, Jid Ali, Jurdab, Sanad, Al Kharijiyah, Kawrah, Mahazza, Wadyan, Salmabad, Tubli, Riffa, A’ali, Al Qadam, Jamala.

For more information or to request a quote, please contact us.

View Product: Click here