Dynemix India Engineering Pvt. Ltd. is a leading Manufacturer, Supplier, and Exporter of Solid Material Conveying System in United States.

About Us:

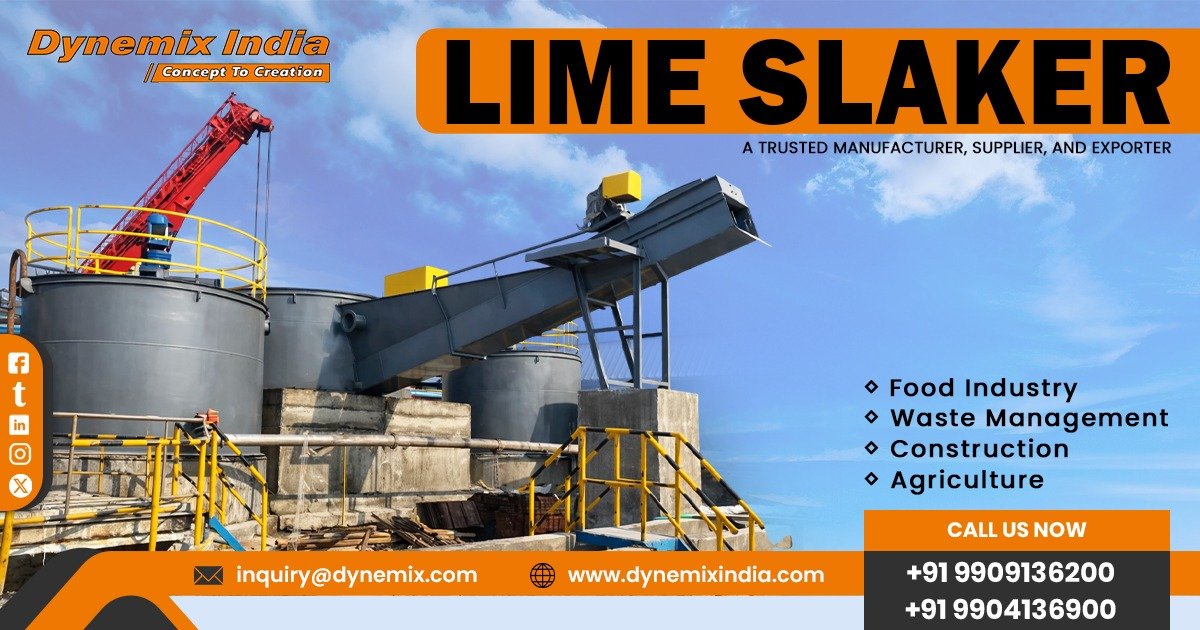

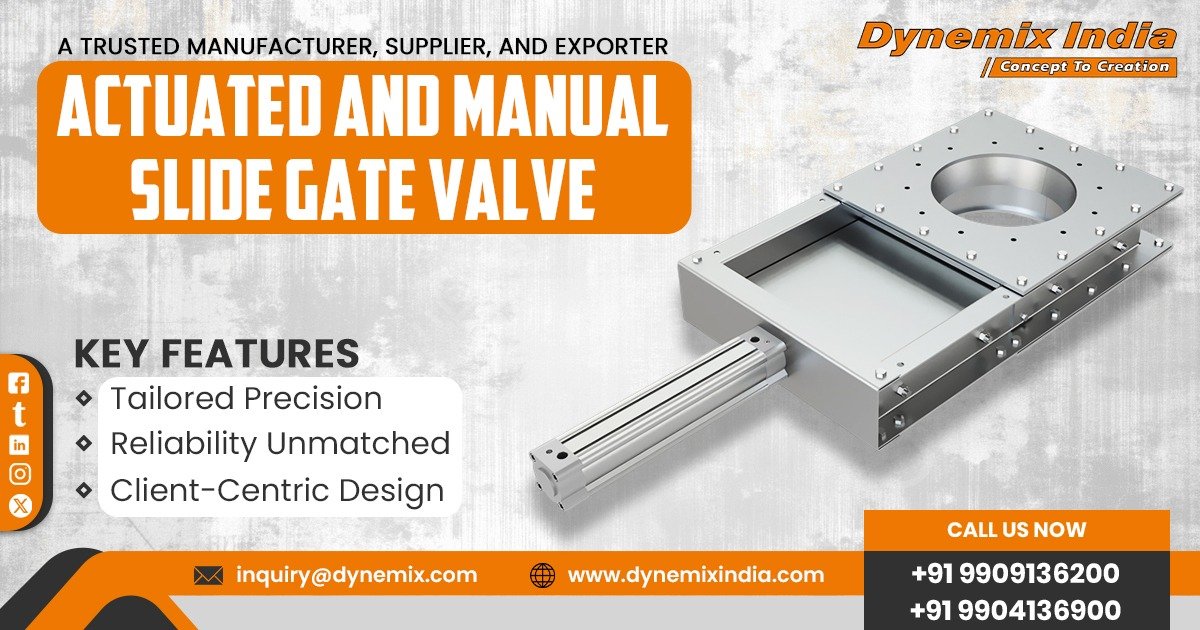

Dynemix India Engineering Pvt. Ltd., based in Ahmedabad, Gujarat, India, is a technology-driven specialist in design, manufacture, and turnkey commissioning of material handling systems—ranging from belt, drag‑chain, tube‑chain conveyors to dense‑phase pneumatic systems and more

Global Reach: With 30+ years of experience, 50+ completed projects, 300+ clients, and 15+ countries served, Dynemix is a trusted exporter to the USA, including all 50 states.

Engineering Excellence: Offering in‑house mechanical and electrical design, advanced manufacturing, SCADA integration, and strong after‑sales service under the leadership of MD Mr. Jignesh Patel

Overview of Solid Material Conveying Systems

Solid material conveying systems transfer bulk solids—such as powders, granules or pellets—between points using mechanical or pneumatic means.

Dynemix provides a wide portfolio: belt conveyors, drag-chain conveyors, tube-chain conveyors, dense-phase pneumatic conveyors, and more

Features:

Minimal Maintenance: Robust designs with reduced moving parts for increased uptime

Dust‑Free & Compliant: Enclosed systems for safe & environmentally compliant operations .

High Load Capacity: Up to heavier throughputs—e.g., Drag Chain conveyor handling 200 TPH.

Energy Efficiency: Dense-phase pneumatic systems operate at low air flow but high pressure Quiet, Safe Operation: Low-noise design with safety accessories like zero-speed switches.

Working Process of Solid Material Conveying Systems

Plug Formation: Controlled low‑velocity, high‑pressure air forms plugs of material in a sealed pipeline

Plug Propulsion: Air pulses push plugs gently, preserving integrity of abrasive or friable solids.

Separation & Delivery: At destination, plugs disintegrate and material is discharged.

Minimal Air Usage: Achieves 1–80 tons/hour with operating pressure up to 6000 mbar(g)

Auxiliary Equipment: Includes air movers (e.g. screw, claw compressors), blowers, SCADA, diverter valves, etc.

Applications Across Industries:

Food & Pharma: Safe, hygienic powder handling (GMP-compliant, stainless steel).

Chemical & Petrochemical: Abrasive and sensitive particulate transport.

Mining & Minerals: Heavy-duty drag-chain systems for ores & minerals.

Cement & Construction: Bulk cement transfer via tube/belt conveyors.

Plastic/Textiles: Granule and pellet conveying.

Power & Biomass: Coal, biomass conveyance, ash removal.

Recycling & Waste: Dust-free transport in plants.

FAQs:

Q: Which materials suit dense-phase conveying?

A: Ideal for abrasive, friable, cohesive powders, granules, pellets.

Q: Maximum conveying distance?

A: Up to 200–400 m, customizable based on material.

Q: Do you support US installations?

A: Yes – remote & onsite technical support, installation & training across all US states.

Q: Is system suitable for food/pharma GMP environments?

A: Yes – stainless steel & cleanroom compliant options available.

Q: Energy efficiency?

A: Low air usage leads to highly efficient performance vs traditional pneumatic systems.

Q: What after‑sales support is provided?

A: End‑to‑end turnkey service with SCADA, commissioning, operator training, spare parts & maintenance support.

Dynemix India Engineering Pvt. Ltd. is an Exporter of Solid Material Conveying System in United States including location in New York, Chicago, Philadelphia, Los Angeles, Houston, San Diego, Phoenix, Dallas, San Antonio, Austin, San Jose, Las Vegas, San Francisco, Oklahoma City, Seattle, Boston, Denver, El Paso, Nashville, Fort Worth, Charlotte, Indianapolis, Jacksonville, Columbus, Washington, D.C., Tucson, Fort Collins, Detroit, Baltimore, Kansas City, Santa Ana, Salt Lake City, Daly City, Kansas City, Honolulu, El Monte, Virginia Beach, Provo, Boise, Fort Wayne, Sioux Falls, Lincoln, Nampa, Carlsbad, Atlanta, Miami, Portland, Colorado Springs, Albuquerque, Oakland.

For more information, visit Dynemix India Engineering Pvt. Ltd.

View Product: Click here