Home » Product » Bulk Powder & Material Handling Equipments » Manual Bag Dumping Station

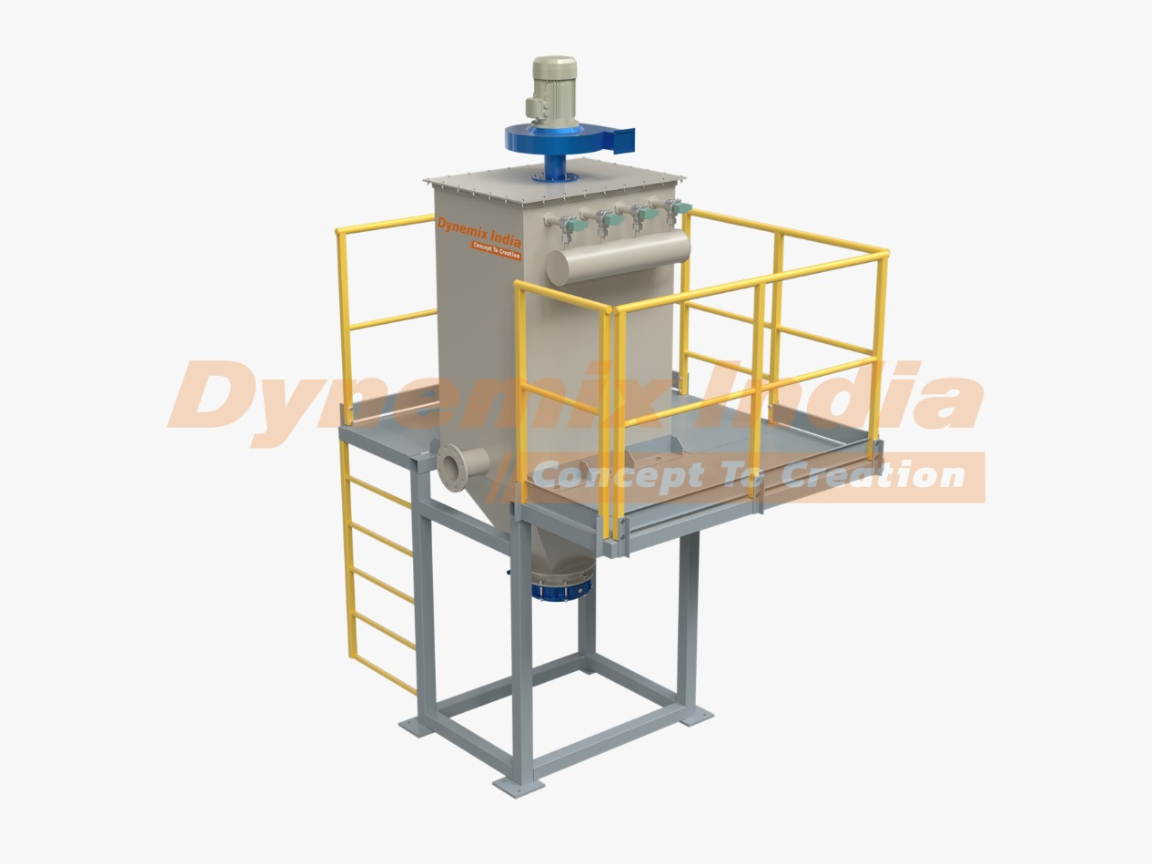

Dynemix’s manual Bag Dump Stations are expertly designed to facilitate the effective unloading of small-volume bags while significantly reducing product loss due to dust emissions. These innovative stations play a crucial role in enhancing worker safety, minimizing housekeeping requirements, and ensuring that your materials remain in the production flow where they are needed most. Constructed from durable steel or stainless steel, Dynemix Bag Dump Stations feature an ergonomic design that promotes ease of use.

This design enables bulk materials to be stored and transferred to the production line without risking air contamination from dust during the bag opening and discharge process. Each station is equipped with advanced dust extraction nozzles or integrated filters, ensuring a cleaner working environment and compliance with safety regulations. The operation is straightforward and user-friendly. The operator can place the bag on a shelf, either manually or with the assistance of a vacuum manipulator, and position it over a screen that is strategically placed above the powder evacuation hopper. Once the bag is securely in place, the operator performs a cutting operation to open it. After this, they can easily open the door of the station and shake the empty bag to ensure that all materials are fully discharged.

| product | Manual Bag Dumping Station |

| Power Source | 1 |

| Voltage | 415V AC |

| Lifting Capacity | 50 |

| Usage/Application | Powder |

| Material | SS/MS |

WhatsApp us