Bulk solids can occasionally experience lumping or caking, which causes the individual solids particles to aggregate into a larger chunk that, in certain situations, might measure several centimeters or even dozens of centimeters. When this occurs, lumps can obstruct pipes and other equipment, lower a production process’s throughput and/or quality, and cause serious operational issues.

The purpose of this top-tier Indian manufacturer, exporter, and supplier of our products is to smash the agglomerate and recover the individual particles while preserving the bulk solids’ characteristics, particularly their flowability.

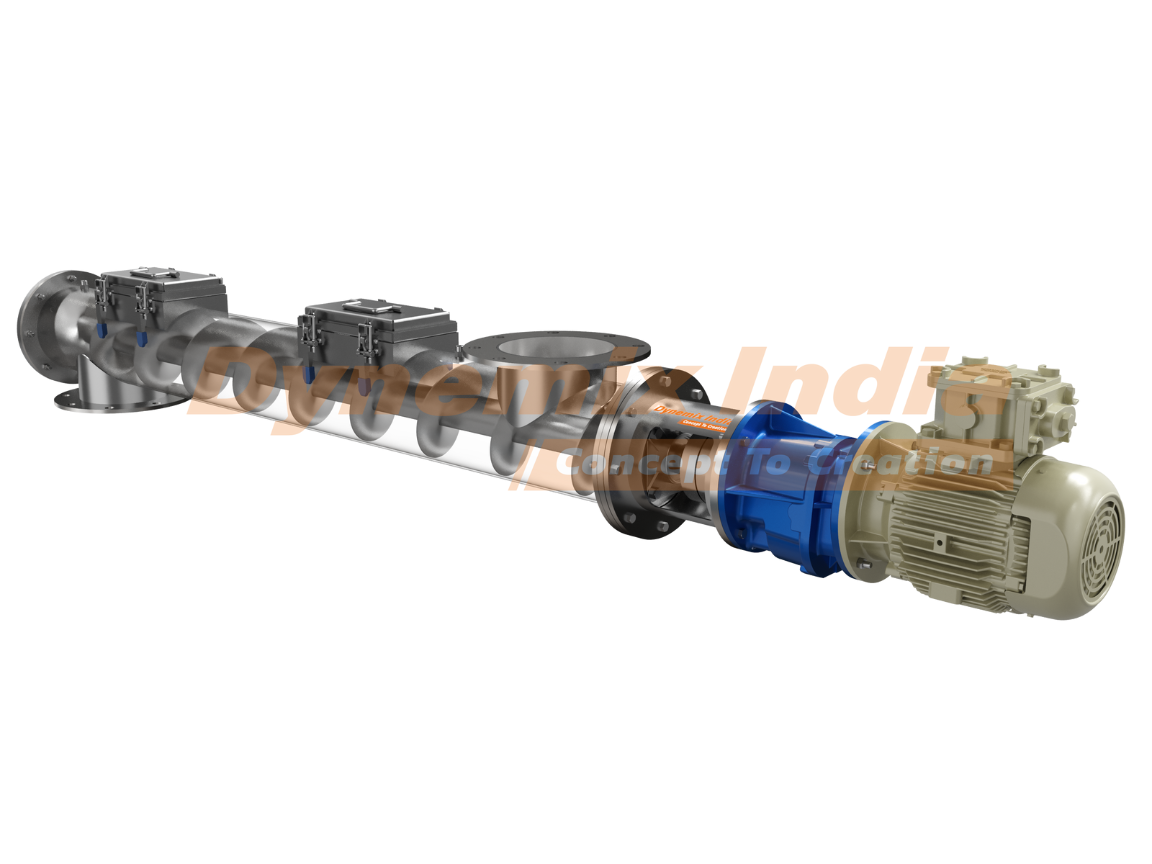

Certain designs have the “combs” on the side of the lump breaker and two counter-rotating shafts. Other systems, which size the material exiting the breaker by employing a perforated plate and beaters of some sort, are based more on hammer mill principles.

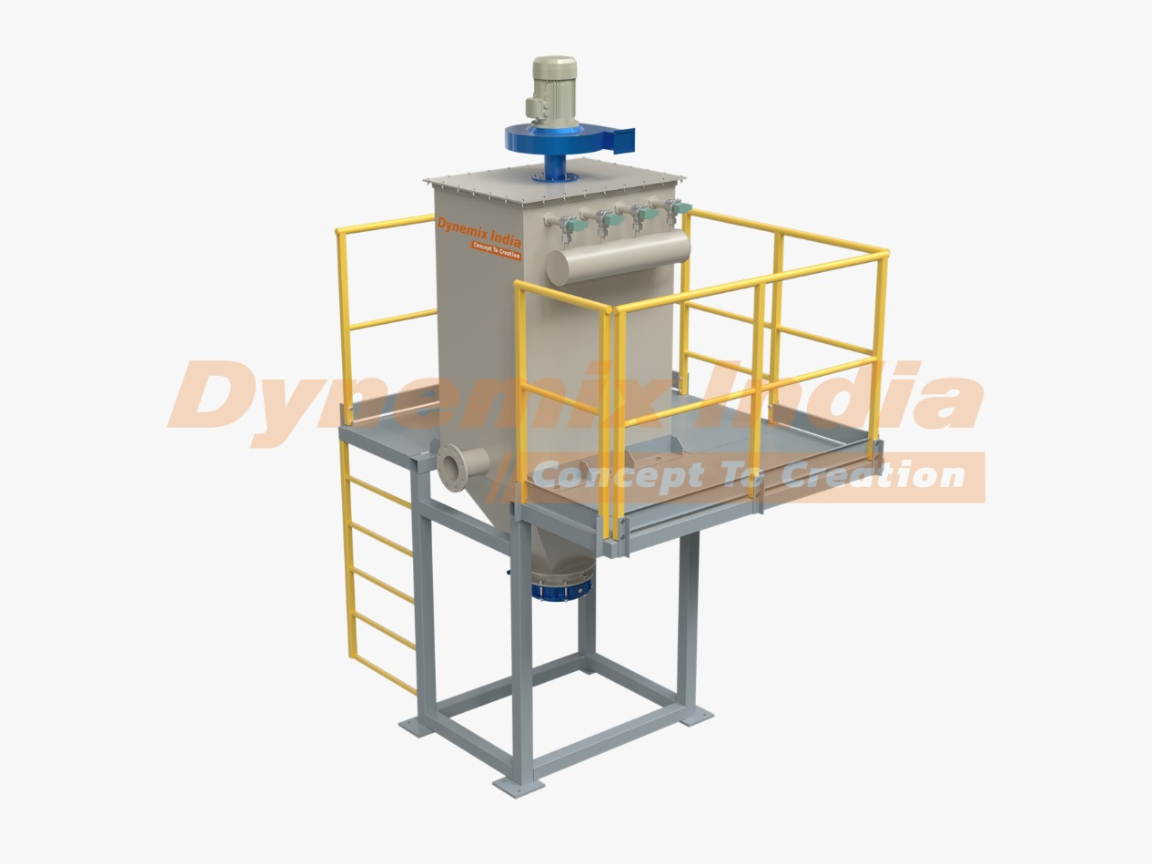

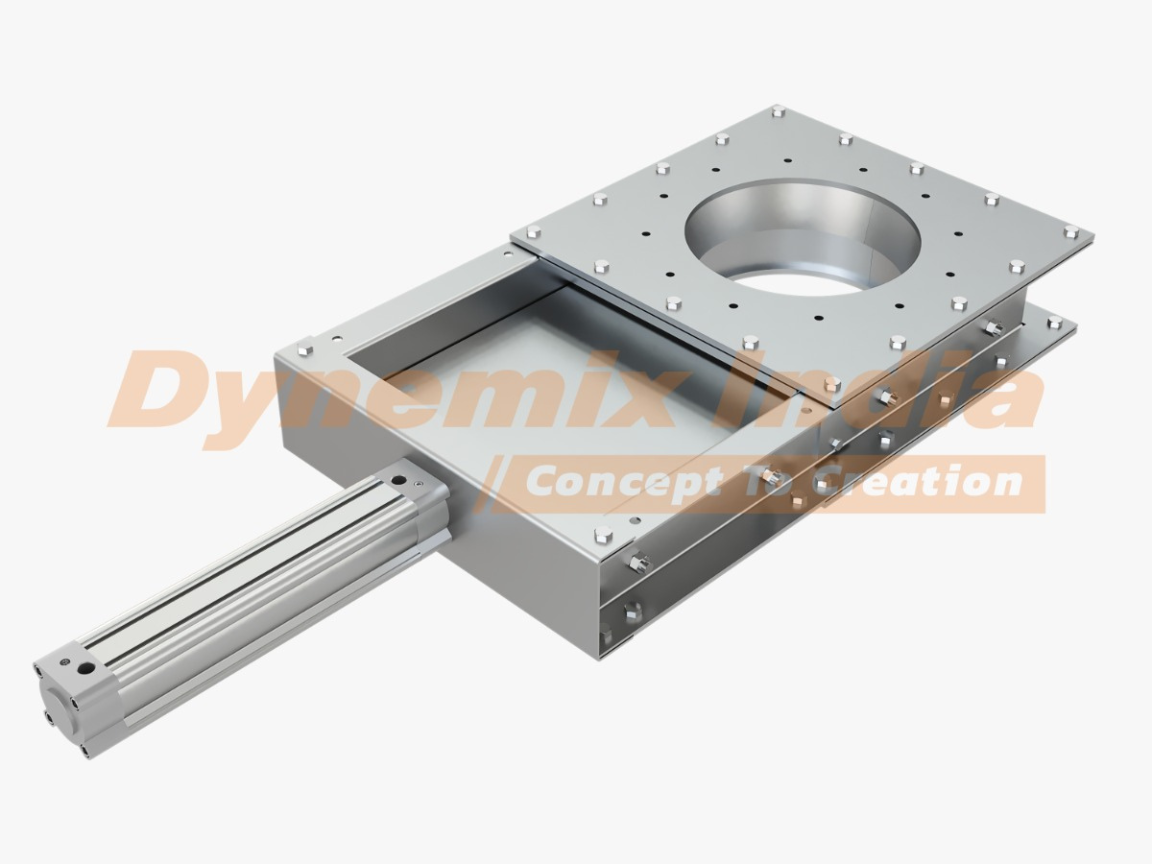

A vibrating tube, a screw conveyor, or an airlock rotary valve are examples of dosing equipment that can be used to (at least roughly) manage the feed to the our products. The outlet must always be free of product in order for the shaft to rotate; alternatively, the breaker may be operated in load, below a hopper.

| Material | Mild Steel |

| Voltage | 240V |

| Frequency | 50 Hz |

| Surface Treatment | Painted |

| Capacity | 25 TPH |

| Power | 15 kW |

WhatsApp us