Dynemix India Engineering Pvt. Ltd. is trusted Manufacturer, Supplier and Exporter of Bagging System in Sweden.

We are based is based in Ahmedabad, Gujarat, India.

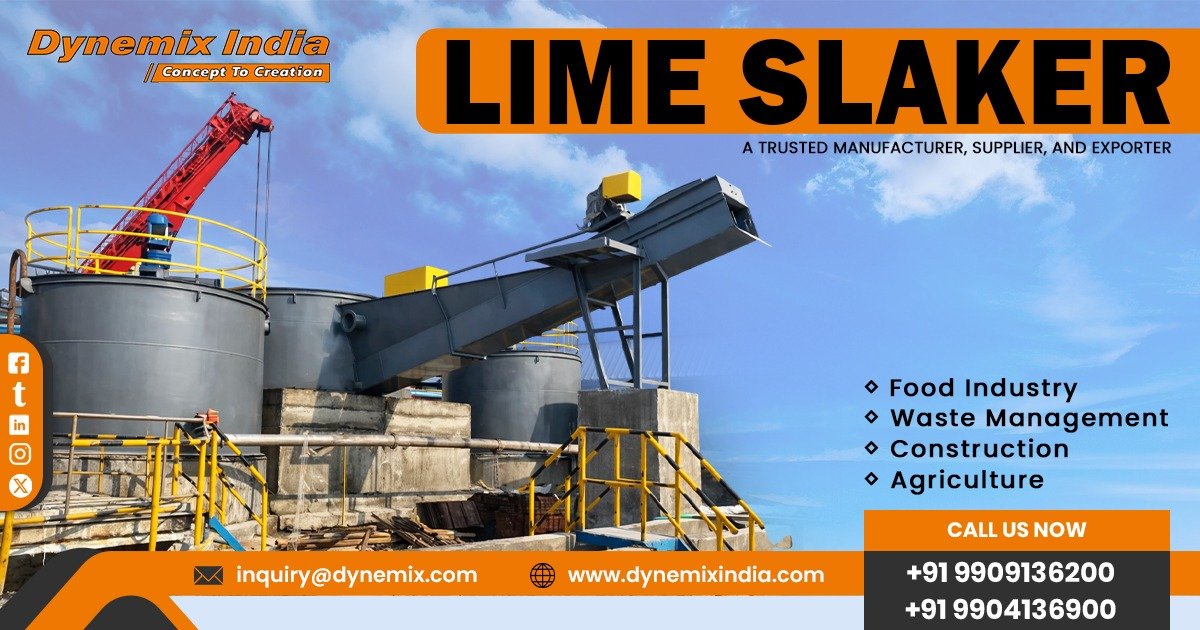

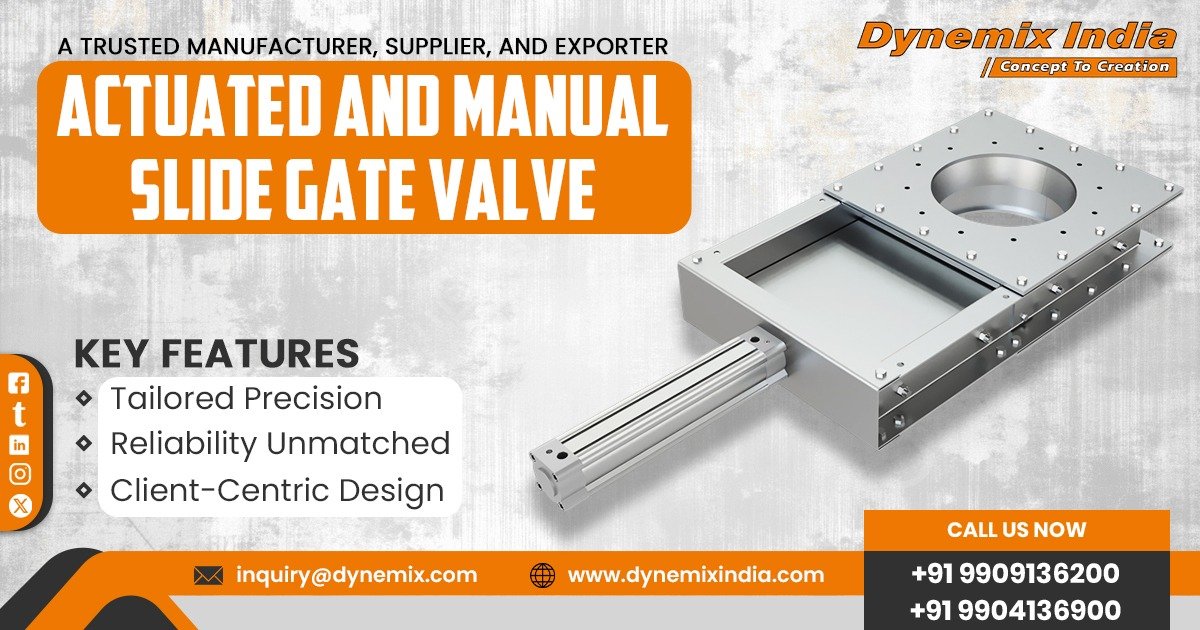

Dynemix is a leading manufacturer of high-quality industrial equipment, specializing in solutions for a range of industries including construction, chemicals, agriculture, mining, and cement

What is a Bagging System?

A Bagging System is an automated or semi-automated machine designed to efficiently fill and seal materials into bags.

These systems are crucial in industries that require bulk packaging, such as cement, fertilizers, seeds, grains, sand, and chemicals.

Dynemix offers both manual and automatic systems, crafted for high-speed, precise, and durable performance, tailored to meet the specific needs of each industry.

Features of the Dynemix Bagging System:

Automation Options: Fully automated or semi-automatic modes available.

High-Speed Operation: Fast and accurate filling mechanism.

Precision Weighing: Digital weighing system ensures accurate measurements.

Versatile Bag Compatibility: Works with various bag types, including PP, jute, and kraft paper.

User-Friendly Interface: PLC controls make operation straightforward.

Corrosion-Resistant: Stainless steel construction for long-lasting durability.

Dust-Free Filling: Minimizes spillage and dust emissions during the filling process.

Low Maintenance: Designed for minimal upkeep and maximum operational life.

Benefits of the Dynemix Bagging System:

Boosted Productivity: Increases output by speeding up the bagging process.

Cost Efficiency: Reduces labor costs and minimizes material wastage.

Accurate Weighing: Ensures consistent, precise filling with no over- or underfilling.

Heavy-Duty Engineering: Built to meet international standards for durability and performance.

Safe & Clean Work Environment: Limits exposure to dust and hazardous materials.

Ease of Use: Quick installation and intuitive operation for seamless integration.

How the Dynemix Bagging System Works:

Material Feeding: Bulk material is fed into the system via a conveyor or hopper.

Weighing Unit: A digital scale accurately measures the material for each bag.

Bag Placement: Bags are positioned manually or automatically under the filling nozzle.

Filling: The system dispenses material into the bag with minimal dust and spillage.

Sealing: Operators seal bags securely using stitching, heat sealing, or tying methods.

Discharge: A conveyor or pallet moves filled bags for easy shipment.

Industries Using Dynemix Bagging Systems:

Construction: Cement, sand, fly ash, and ready-mix products.

Agriculture: Seeds, grains, animal feed, fertilizers.

Chemicals & Pharma: Powders, granules, additives, and other fine materials.

Mining & Minerals: Limestone, dolomite, bentonite, and other bulk materials.

Industrial Manufacturing: Plastics, polymers, and resin compounds.

Exporters: Bagging solutions for standardized export-grade materials.

Dynemix India Engineering Pvt. Ltd. is Exporter of Bagging System in Sweden including location in

Stockholm, Gothenburg, Uppsala, Malmö, Örebro, Linköping, Helsingborg, Jönköping, Umeå, Norrköping, Västerås, Karlstad, Kalmar, Eskilstuna, Ystad, Sundsvall, Halmstad, Gävle, Karlskrona, Lund, Kiruna, Växjö, Luleå, Östersund, Falun, Södertälje, Borås, Visby, Trollhättan, Falkenberg, Ängelholm, Varberg, Norrtälje, Hässleholm, Västervik, Nyköping, Arvika, Enköping, Nynäshamn, Söderhamn, Trelleborg, Härnösand, Karlshamn, Uddevalla, Lidköping, Landskrona, Skövde, Oskarshamn, Örnsköldsvik, Alingsås, Kungälv.

For more information or to request a quote, please contact us.

Website: www.dynemixindia.com

Phone No: +91 9909136200 | +91 9904136900

Email Id: inquiry@dynemix.com

View Product: Click here