Dynemix India Engineering Pvt. Ltd. is a reliable Manufacturer, Supplier, and Exporter of Lime Feeding System for Boilers in Canada.

Our Manufacturing unit is located in Ahmedabad, Gujarat, India.

Dynemix India Engineering Pvt. Ltd. specializes in the design, manufacturing, and export of high-performance engineering systems tailored to meet the diverse needs of industries around the globe.

With a strong focus on quality, innovation, and customer satisfaction, Dynemix has carved a niche in delivering turnkey solutions across sectors like power, chemical, cement, steel, water treatment, and more.

Our presence is steadily growing in international markets, including Canada, where industries are seeking reliable and efficient systems for pollution control, fuel handling, and water treatment.

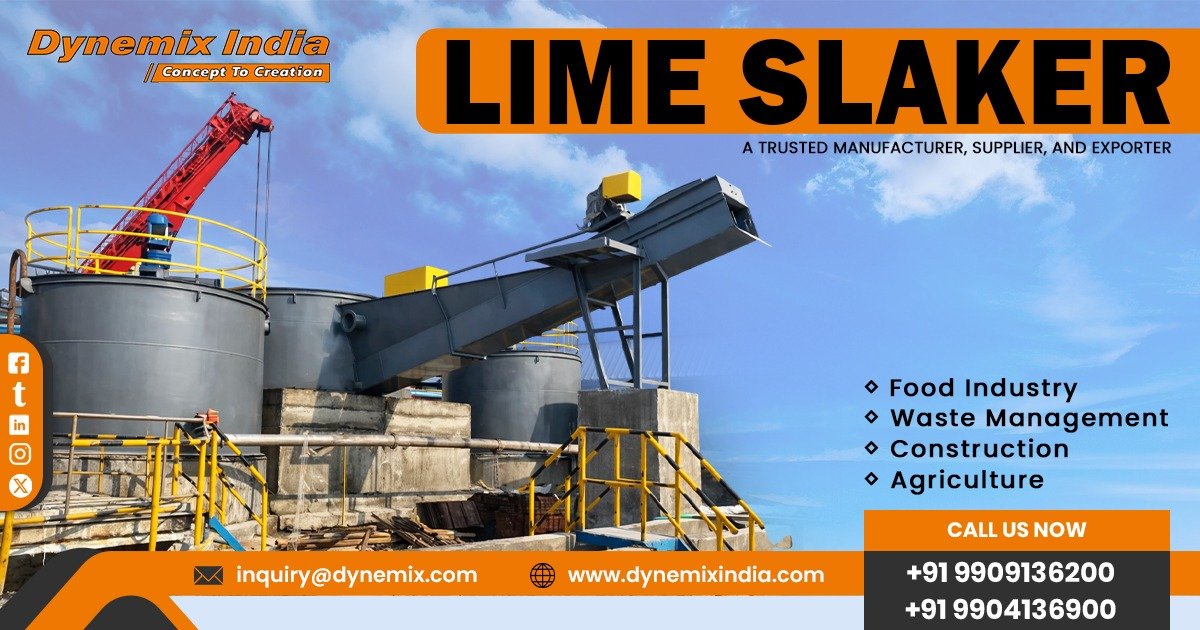

One of our most demanded products in the Canadian market is the Lime Feeding System for Boilers—an essential solution for industrial boilers requiring effective pH control and flue gas treatment.

Lime Feeding System for Boiler – What is it?

The Lime Feeding System for Boiler is a fully automated, precision-engineered system used to feed lime powder or slurry into boilers.

It plays a critical role in controlling the pH of water and reducing harmful emissions like SOx (sulphur oxides) in the flue gas.

Lime, a widely used alkaline substance, reacts with acidic components to neutralize them, ensuring regulatory compliance and extending boiler life.

Why Choose Dynemix for Lime Feeding Systems in Canada?

In-House Manufacturing: Full control over quality and delivery timelines.

Turnkey Solutions: From design and installation to after-sales support.

Rugged Design: Built for Canadian climatic and operational conditions.

Proven ROI: Improved efficiency, reduced emissions, and minimal downtime.

How Does the Lime Feeding System Work?

The working process of the Lime Feeding System typically involves the following stages:

Storage and Transfer: You store lime in a silo or hopper, then transfer it using a screw conveyor or pneumatic conveying system.

Dosing: A volumetric or gravimetric feeder accurately controls the flow of lime into the system.

Injection: A specially designed injector or slurry mixing tank injects the lime into the boiler water or flue gas stream.

Mixing and Reaction: In the boiler system, lime reacts with acidic gases (like SO₂) or acidic water components, neutralizing them to maintain pH balance or reduce emissions.

Control and Monitoring: A centralized control panel, often integrated with PLC/SCADA, allows real-time monitoring, adjustments, and alerts for preventive maintenance.

Uses of Lime Feeding System for Boiler

The lime feeding system is used in a variety of applications including:

Flue Gas Desulfurization (FGD) in coal-fired power plants

Water pH Control in boiler feedwater treatment systems

Chemical Reaction Control in process boilers

Ash Conditioning to reduce fly ash corrosion

Sludge Treatment in thermal plants

Environmental Compliance in municipal and industrial boilers

FAQs:

Q1: Is lime feeding safe for my boiler system?

A1: Using a controlled system like Dynemix’s, lime feeding is safe and improves boiler efficiency, performance, and lifespan.

Q2: What type of lime can be used?

A2: Our systems support hydrated lime, quicklime, and lime slurry, depending on the application.

Q3: Can your system be installed in existing boiler setups?

A3: We offer retrofitting solutions that integrate seamlessly with your existing infrastructure.

Q4: How much maintenance does the system require?

A4: Our systems are low maintenance. Routine checks and minor servicing ensure smooth operation.

Q5: Do you provide installation and support in Canada?

A5: Yes. We collaborate with local partners and provide remote or on-site assistance for installation, commissioning, and training.

Dynemix India Engineering Pvt. Ltd. is an Exporter of Lime Feeding System for Boilers in Canada including location in Toronto, Vancouver, Ottawa, Montreal, Québec City, St. John’s, Calgary, Saint John, Edmonton, Victoria, Winnipeg, Saskatoon, Windsor, Abbotsford, Lethbridge, Fredericton, Moncton, Halifax Regional Municipality, Barrie, Oshawa, Sherbrooke, Kelowna, Thunder Bay, Trois-Rivières, Greater Sudbury, Hamilton, Kitchener, Regina, Kingston, London, St. Catharines, Surrey, Burnaby, Stratford, Brandon, Red Deer, Guelph, Belleville, Brantford, Prince George, Peterborough, Sault Ste. Marie, Medicine Hat, Saint-Jean-sur-Richelieu, Nanaimo, Kamloops, Chilliwack, Drummondville, Granby, Saint-Hyacinthe, Grande Prairie.

For more information, visit Dynemix India Engineering Pvt. Ltd.

View Product: Click here